New Technology Offerings Make Sourcing Easier

Internet technology has addressed just about every facet of the apparel business. But only recently has it delved into the world of global sourcing. With the downsizing of domestic production over the past decade, the largest moves to offshore production have come in the past five years. Now, information technology (IT) companies are responding by automating the management of the steps that come with sourcing offshore.

This involves everything from finding factory partners to securing requests for quotations (RFQs), product-development tracking and quality control. Only a few companies have addressed sourcing at the IT level so far.

Miami Lakes, Fla.–based New Generation Computing Inc. (NGC) has developed a sourcing software system that manages and monitors pre-production, production, and packing and logistics steps specifically for the apparel and sewn-products industries.

The system was borne out of the shop-floor management system that NGC developed in the mid-1980s to monitor factory output and measure labor for costing purposes. That system evolved further in 1998 to include tracking functions. The company developed the current e-SPS (sourcing and production system) in 2000 as more companies began looking to Asia, the Caribbean basin and Central America for their production needs.

E-SPS, according to NGC, is the industry’s only true sourcing control system. Some enterprise resource planning (ERP) and product lifecycle management (PLM) systems cover steps in the supply chain but not from the sourcing perspective, said NGC’s vice president of sales, Fred Isenberg. “Aside from factories getting out [of the United States] was the compression of time and proliferation of SKUs [stock-keeping units] that companies were facing. Things were farther away, and there was a shorter amount of time to deal with,” he said.

Isenberg said companies communicated with their suppliers through facsimile, telephone and, more recently, e-mail but that was not efficient enough for many.

“There were too many non-value-added steps and non-integrated steps involved,” he explained. “Things that took a week should have taken one day. Our customers were moving offshore and were giving up lots of visibility, so we needed to have a system that communicated with their global factories.”

Increasing visibility

The e-SPS system was developed to bring manufacturers, importers and retailers closer to their supply chains—not geographically but through the Internet.

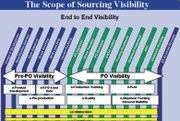

The system allows managers to view the production process from the RFQs and bids level to the point when garments are being shipped on a truck or boat to a distribution center.

Isenberg said the backbone behind a sourcing management system is visibility—that is, knowing what is happening at all points in the supply chain. Through e-SPS, all events are tracked through the Internet and are accessible to all trading partners, so if a shipment gets delayed or a lab dip is not received, all parties know about it through a central database that is updated automatically by suppliers and managers.

By enhancing visibility, there is increased speed-to-market and efficiency. Isenberg said timing is critical for the apparel industry. “One of our clients, Wilsons Leather, has one shot all year to make a profit [because of its seasonal business]. So Web-based connectivity is critical,” he said.

E-SPS, part of NGC’s SQL series, can work as a standalone installation. Many companies are using the system as part of their “Best of Breed” strategies, incorporating it with other software applications considered to be the best in their fields, whether those be ERP, PLM or CAD.

Among the processes that e-SPS addresses are specification creations, product-development tracking, purchase-order creation, supplier/factory scorecards, scan/pack, bar-code processing with advanced shipping notices, pre-production calendaring, supplier/factory order acknowledgements, logistics tracking and exception reporting.

Factories and suppliers are not required to have the software, only an Internet browser.

Koret of California, a division of Kellwood Co., is one company using the system. Koret has shaved two weeks off its cycle time with e-SPS, according to Mark Goldberg, vice president of worldwide operations. Goldberg said having live, immediate information has been the driving factor to increasing speed-to-market. The system has also helped make the division more flexible, allowing it to change purchase-order quantities and adjust styling, he added.

Matchmaking online

New company Source Global On-Demand, better known as SourceGo, is also using Internet technology to help companies find the right factories for their needs. The Washington, D.C.–area company formed in January to bring manufacturers, importers, retailers and other private-label specialists together with offshore factories that are pre-qualified and categorized through specific criteria—such as whether they have a social compliance certificate, how far they are to ports or consolidators and what their technology requirements are.

SourceGo specializes in China and Asia sourcing but plans to branch out to cover emerging markets such as India and Central America. The company’s staff is made up of veteran technology and sourcing executives who have key contacts with government agencies such as the China National Textile & Apparel Council and with owners of small, mid-sized and large factories. Using its resources, SourceGo can provide RFQs, sample requests and supplier scorecards from factories that match their needs.

“We’ve put all the features and sourcing activities that a major company [typically has] and pooled the costs,” said company principal Warren Hartenstine, a former Gerber Technology Inc. executive. “We create direct relationships with factories.”

SourceGo provides its service on a subscription basis that is broken into four categories based on the level of services offered. Subscribers can pay as little as $50 a month. Services include RFQs, costing scenarios, sampling-process management and supplier scorecards.

The company is also being powered by NGC’s e-SPS software to help its clients track orders through the supply chain. The American Apparel & Footwear Association recently endorsed SourceGo as the provider of online sourcing needs for its members.

SourceGo also has offices in Shanghai, China, and Miami.

For more information on both companies, visit www.sourcego.com and www.ngcsoftware.com.