Shapely Shadow Goes to the Net for Fit Sessions

Malibu, Calif.–based Shapely Shadow is bringing its 3-D fitting technology to the Internet.

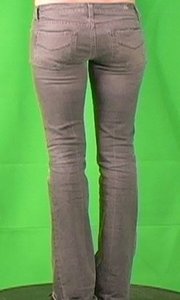

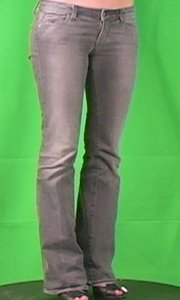

FastFit360 is the company’s signature software, which employs stop-action digital imagery of garments as worn by fit models to enable designers, manufacturers and retailers to view a 3-D image of a garment, rotate those images 360 degrees and make adjustments as needed.

The system has worked well for companies with offshore production facilities because it provides visual communications, which is sometimes easier to express than words, said company founders Ilona Foyer and Roxy Starr.

The technology employs a user-provided video system whose images can be converted to simple jpeg format and captured at any angle. The models are placed on a turntable while being photographed. It’s similar to the old flip-book animation used in early television, Starr said. Unlike virtual-garment production using CAD, FastFit uses real images of actual models or dress forms.

“This is the fit room of the future,” she said. “It’s sometimes difficult to communicate in words with factory workers whose native language is not English. Part of fit is seeing,” she said.

Many companies take still digital pictures of the front and back of a garment, which misses many aspects of total fit, Starr said.

“Why do it that way when you can do it in 360 degrees?”

By June the company will offer FastFit as an on-demand software on a service basis in which users pay only a monthly fee. It currently provides the system on a licensed basis, which requires software installation and management. The new format offered via the Internet is hosted and frees up hard-disk space for users and lessens the confusion of maintaining file libraries because everything is on the Internet, Foyer explained.

Early adopters of FastFit include Macy’s, Chico’s, Gap and Victoria’s Secret. Companies saved money and shaved time off traditional methods, which can require sending multiple e-mails back and forth or having to send a fit model to remote factories.

A fit model in New York can charge $350 per hour. Add to that the cost of producing samples, and the return on investment can come quickly for some companies, Foyer and Starr said. FastFit can cut sample iterations by 30 percent to 50 percent for some companies, they said. For most companies, that means reducing the number of samples per style from the usual six or seven down to three or four.

The system can also product efficiency reports and allows customers to rate suppliers’ quality levels.

“Everybody’s talking about PLM taking care of all these steps, but it doesn’t [cover the fitting process],” Foyer said. “You can put in your trim and factory costs, but who takes care of the fitting?”

In addition, there’s more visibility extending to departments such as quality control because they can also view and provide input on garments in progress, she said.

For more information, visit www.shapelyshadow.com. —Robert McAllister