Coup D’Etat: Made in U.S.A.

The clickety-clack of hand-loom knitting machines echoes through the downtown L.A. Fashion District offices of Coup D’Etat.

Three knitters, with years of experience behind them, each stand in front of a machine, intricately making sweater panels that will take two hours to complete. Later the panels will be linked and the sweater finished by weaving in ends.

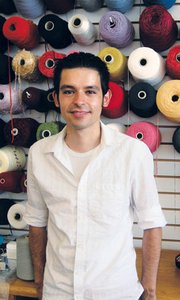

Not far away, Andrés Alves sits at his desk, light streaming in through the tall windows of the Merchants Exchange Building on Los Angeles Street. A hodgepodge of sweater patterns hangs from a rolling rack nearby. Sweater samples dangle from another rack. A colorful wall of yarns is at the end of the office.

Alves is in the rare business of knitting sweaters on a micro basis, where minimum orders don’t exist. During any one month, his tiny company whips up 300 to 400 sweaters for luxury labels that can afford the higher prices a “Made in USA” label commands. He has made sweater samples for Marcia Patmos, the New York designer whose new M. Patmos label is sold at high-end specialty stores and Barneys New York.

He has worked in the past with Julio Santiago, the Argentine-born designer who moved to Los Angeles to create a very exclusive line of sweaters that retails for around $600. His Santiago line of tops in super-kid mohair, royal alpaca and cashmere sells at Los Angeles–area stores such as Fred Segal, TenOverSix and Brigade LA. “He is very responsible and pays attention to detail and is very creative,” Santiago said. “There are not many knitting warehouses in Los Angeles, so what usually happens is they take more orders than they can produce, and that creates problems for small labels such as mine. The bigger labels get priority, and deals aren’t always kept. But Andrés is real responsible, runs a really tight operation and means what he says.”

Alves has only been in the sweater knitting business for one year. A 2010 graduate of the Fashion Institute of Design & Merchandising in Los Angeles, he worked as a designer for one year with John Ward, who was one of the co-founders of luxury T-shirt label Three Dots. Ward now has his own contemporary clothing line, called Maggie Ward.

At Maggie Ward, Alves said, he developed six sweater silhouettes for Maggie Ward’s Fall 2011 collection, some that were picked up by Nordstrom and Barneys New York.

Sweaters, Alves found, were his passion, something that might come from growing up in La Paz, Bolivia, where the city’s 12,000-foot-high elevation makes wearing sweaters almost a year-round activity.

Through a FIDM contact, Anne Bennion, chair of the fashion knitwear and textile design departments, Alves heard there was a small downtown L.A. sweater knitting operation for sale from Aida Ley, who had been knitting sweaters for movie stars, the film industry and top-notch designers for more than 20 years. “When I saw the operation for the first time, I felt it had potential to be turned into a small manufacturing place,” said Alves, who had also done some free-lance designs for Ball of Cotton, a sizeable sweater manufacturer in Commerce, Calif.

He was fortunate to inherit one of Ley’s principal customers, Elaine Kim, a luxury designer whose self-named label is created out of a studio and store on West Third Street. “Elaine left some pretty big cashmere orders,” Alves said. “She has a loyal following. She also sells her label to some stores in Venice. She orders about four times a year, and each time it is 150 to 200 units.”

Elaine Kim likes to use Alves’ company because it ties in with her “Made in L.A.” theme. She also likes that samples are turned around quickly. “It offers a lot of flexibility for us,” said Jumi Kim, design manager for the Elaine Kim label. “Andrés really is an artisan. He can do things to yarn we would never imagine.”

With 10 hand-loom machines set up and run by three employees, Alves is busy concentrating on creating unique sweater stitches and designs. His specialty is texture and special stitches. He normally combines a number of yarns with one stitch or combines stitches with yarn. Every yarn reacts differently to a stitch.

He pulls out a stack of sweater swatches he has created in all sorts of colors, textures and yarns of viscose, chenille, merino wool, bamboo and linen. “For most of our clients, we show them different things we can do with yarns because most designers are accustomed to working in cut and sew,” he said.

The most popular stitches are tuck stitches, rib stitches, slip stitches, jacquard stitches and Fair Isle stitches.Alves became interested in knitwear while studying at FIDM and competing in a Cotton Inc. “Most Innovative Use of Cotton” contest in 2007 that required students to create looks for a wedding. He won a $5,000 scholarship for his rock ’n’ roll Las Vegas wedding dress, made of a cotton woven fabric. But he saw other students creating three-dimensional effects with knitwear and became fascinated with it.He ended up taking an extra year of classes in the fashion knitwear and textile design department, which taught him a lot. “I really thought that sweaters were knitted on two needles until I went to class,” he remembered.

Alves’ goal now is to build a list of steady clients to keep his shop running and launch his own label. “I think I want to come out with my own sweaters soon,” he said, insisting that the sweater line will not be named after him.

—Deborah Belgum