TECHNOLOGY

3-D Technology Pushes the Envelope for Apparel Companies

While apparel-production software has been around for years, the latest advances in three-dimensional renderings are helping apparel companies cut down on both time and money.

“There is a big, big focus on 3-D these days,” said Franz Heidsieck, marketing manager of fashion product development for Lectra, an international technology provider for apparel and other “soft-material” industries.

The technology has been incorporated into computer-aided design (CAD), product lifecycle management (PLM) and visualization software, as well in body-scanning machines that scan fit models for garment samples and digital avatars.

3-D is about making an idea become real in the virtual world, so as to connect people in different areas and make collaboration easier, Heidsieck said.

Getting the hang of digital draping

Until recently, designers needed to create costly garment samples that were flown back and forth to manufacturers overseas, but with the development of more realistic 3-D representations, they are now able to design and share digital prototypes, which saves time and money.

Brands often have to produce as many as five different samples of each garment and ship them around the world, with each iteration taking a couple of weeks, explained Yoram Burg, president of OptiTex USA, an international company that develops technology solutions for the apparel industry.

“The only ones going home with a big smile on their face are UPS and FedEx,” he explained. “If we can make the skies a little greener and cleaner, then that’s our mission.”

The 3-D designs allow designers to take feedback from production staff and manufacturers and adjust styles digitally for conception, colorways and fit without having to produce costly physical samples that travel back and forth.

OptiTex has been working on honing its 3-D technology for more than 10 years and first brought it to market eight years ago.

Burg refers to the company as a “technology kitchen.” By focusing on technology instead of hardware, OptiTex is able to innovate and deliver technology to market at a faster pace, he said.

“We’re always cooking new technologies—while one version is out, another one is being cooked.”

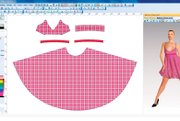

OptiTex offers 3D Runway Creator, a CAD software that also provides 3-D flattening (the transformation of three-dimensional objects’ surface into two-dimensional patterns that make up the draped object); 3D Runway Designer, an application that visualizes garments in their final steps, so users can view them in different colors, textures and embroideries; and 3D Runway Animation, which allows users to animate the prototype and see it in motion on an avatar.

Using technology to capture how a fabric drapes digitally has always been a challenge, but OptiTex developed 3-D fabric simulation for its software by extracting information that can be applied to an algorithm and translated into a 3-D visualized soft object.

The process starts with applying the right fabric properties. “You cannot call a fabric mill and ask them how Lycra or cotton will drape in 3-D. There are services and technologies to test fabrics, and knowing how to tell the difference of how each one will drape in 3-D is the magic of 3-D,” Burg said.

When developing its software, the company worked closely with North Carolina State University to study the behavior of fabric in a 3-D environment. It also introduced a testing device based on Mark-10 testing equipment, which tests fabrics for sheerness, weight and movement, all of which are later simulated in 3-D.

Like OptiTex, Lectra has also developed its own software to capture realistic fabric draping in 3-D.

Textile labs can perform tests that measure attributes such as stiffness, density and drape, and users can take the numbers and plug them into the software to simulate the fabric, explained Stacey Charbin, Lectra’s fashion marketing director.

Fabric testing and modeling are especially crucial when working with sportswear companies that are inventing new, cutting-edge fabrics with specific physical properties, Charbin explained. In these cases, the companies usually work with Lectra to properly model the fabric within the software.

3-D body scanning

Advances in 3-D also have led to progress in body-scanning technology. Over the years, the technology has improved and become cheaper, which has meant easier access for more people, Charbin said.

“3-D body scanners were rare or didn’t exist. So back in the day, if you wanted to develop a garment, you had to develop the fit, develop the pattern, find the fabric and the person to put it on, and measure them by hand,” she said. “Now, you can buy a 3-D body scanner for $5,000.”

Using 3-D avatars instead of live models has provided multiple solutions.

“We never imagined the possibilities [available now] that we could never do in the physical world,” Charbin said.

By using a digital avatar, designers can change the transparency of fabric to check for fit on areas of the body that are hard to see and difficult to fit properly, such as between the legs and under the arms, and patternmakers can easily check for errors.

Designers can also use 3-D to sketch an idea for a garment and experiment with style. “It’s a great way to see it in a very visual way, and you can make as many modifications as you want. It’s extremely fast, and it will cost a lot less,” Charbin said.

They can easily add or take away colors, pleats, buttons and different details, then digitally share 3-D snapshots instead of having to mail a physical prototype. The digital snapshots also allow comments and annotations for feedback from other staff.

“The collaborative aspect of technology has exploded,” she said. “It’s a tool for patternmakers and developers to see what they’re working on in 3-D, live, without having to make it.”

Lectra has incorporated 3-D technology into its PLM software, Lectra Fashion PLM, as well as into Modaris V7, the latest version of its pattern-making software package, which was designed to manage the entire design process.

“[3-D technology] has benefits not only for patternmakers but for the entire design and production team,” Charbin said. “Usually, a team of people are not in the same building, and sometimes they don’t even speak the same language, so visual is the best way to communicate—it’s a language we all understand.”