TECHNOLOGY

Bringing Pattern-Digitizing Technology to the Forefront

In this digital era, companies are now able to render designs in 3-D, manage production with sophisticated PLM systems, and even produce animated avatars to model their clothes, but some businesses and small designers are still working with paper patterns.

“Computer software is expensive, and if you’re starting out, it’s a lot cheaper to buy paper and pencil and scissors,” explained Mary Ann Parker, owner of Marker Express Inc., a Napa, Calif.–based pattern-grading and marking business. Typical patternmaking software can run more than $5,000 or upwards of $9,000 for a package including patternmaking, grading and marker making.

Depending on the type of garment the designer is producing, there are also times when a paper pattern works better, she explained.

“I’ve used computerized patternmaking, grading and marking since the mid-’80s, and for me, the process of making patterns on the computer is very quick compared to making patterns on the table,” she said. “Having said that, if you have very creative-looking garments that require draping and playing with fabric, that doesn’t lend itself well to making patterns in the computer. It’s a hands-on thing—draping is a more creative art form of patternmaking. I know some apparel software has 3-D, but it’s not the same thing. Some people are tactile; they want to play with the fabric.”

For those in the fashion industry still working with paper—either due to limited production runs, smaller budgets or producing a specific type of garment—the ability to digitize these patterns for designing, manipulating, sharing, grading and marking is a necessity.

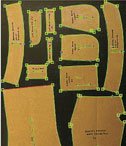

Often, the digital conversion is done with a digitizing table and cursor, where a patternmaker traces the paper pattern into the computer using CAD (computer-aided design) software. It wasn’t until more recently that patternmakers had the ability to convert their paper patterns to digital with a single photograph.

Eight years ago, Audaces, a technology company headquartered in Florianópolis, the hi-tech capital of Brazil, launched Digiflash, a program developed to simplify the process of converting paper patterns by using photography and CAD software, instead of tracing, to capture a digital image of the patterns.

“It’s a lot easier and faster than digitizing by hand,” said Eduardo Lopez, Audaces’ commercial manager for the Americas. “You only need to take a picture, and the software will recognize the size, measurements and everything else. In less than a minute, you can have a paper pattern as a digitized pattern.”

Since introducing Digiflash, Audaces has introduced Digiflash Plus—an advanced software that includes automatic detection of pikes, internal marks and thread direction— and Digiflash XT, a more advanced software with the addition of a measuring table for large patterns. The company debuted the XT, which it touts as a way to “optimize patternmaking,” at the Texprocess trade show in Atlanta in April.

Digiflash XT was designed for working with larger, more complicated patterns, Lopez explained. The complete package comes with CAD software, a large measuring table and a high-resolution digital camera with a special lens. The software calculates the size and measurements of the paper patterns by measuring them against a series of semicircles along the borders of the table. Once users preview the patterns in the software, they can take as many images as they like by clicking a button on the computer.

The technology allows for the automatic detection of several elements of a pattern— including thread direction, internal lines, internal notches and outline notches—and it can be used by upholstery manufacturers, dressmakers or anyone working with oversized patterns.

Sylvie Privat, an independent patternmaker in San Francisco, converts her patterns by hand using a digitizing table. While she has never used a scanner or photo-digitizing software, Privat said she has heard from others about challenges with scanning and photo software picking up miscellaneous marks and incorporating them into the pattern.

“It’s very difficult to have a working pattern through a photo or scan,” she said. “They make too many points, which are not necessary, and it takes a lot more time to clean up a scan of the paper pattern than to trace it with a digitizing table.”

Lopez maintains that the Digiflash software is faster and more precise than digitizing by hand and that it requires less effort on the part of the operator.

“If you don’t have big patterns, you don’t need the table, you can use the wall-mounted digitizer, which is like a blackboard that hangs on the wall,” Lopez said. “You don’t need to fix or mount the patterns. You use magnets to hold them in place. … You take the picture, and that’s it.”

The company has sold Digiflash XT to companies in Mexico and Puerto Rico and is in negotiations to sell the software to companies in the United States, he said.

Audaces creates technology for the apparel, furniture, upholstery, transportation, glass, paper and metalworking industries and has provided apparel software for brands such as Adidas, as well as for companies that manufacture clothing for Nike, Zara, Christian Dior and Diesel, among others.