TECHNOLOGY

Eton Introduces Android-Based Production Solution With Quick Implementation

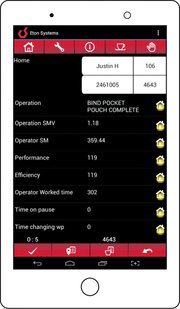

Alpharetta, Ga.–based Eton Systems will release a new mobile application designed to help apparel manufacturers collect real-time production information to help them manage the factory floor.

The ETONnote Shop Floor Control solution will be introduced at the May 13–15 run of the Texprocess Americas trade show in Atlanta. The app, which works on Android devices and transmits information wirelessly, can gather real-time data such as bundle tracking, production counts, operator or team performance, efficiency, and time calculations. The app can also help individual operators gauge their performance based on feedback on operations, pacing and motivational tools.

Eton developed the solution in cooperation with Salem, Va.–based military, industrial and consumer soft-goods contract manufacturer Integrated Textile Solutions, which replaced an existing shop-floor system with ETONnote earlier this year. “We are pleased with the results we have achieved with ETONnote,” said ITS President David Thornhill in a statement. “We saw it as an innovative approach to real-time shop-floor control and a great way to improve and simplify data collection and tracking throughout our sewing operations. After using it for a couple of months, the system is providing production workers with accurate, real-time feedback on their performance throughout the day while enabling management teams to track order status and quality issues better than before.”

Because ETONnote transmits information wirelessly, setup time can be reduced to one week, according to the company. The app can be used on any Android mobile phone or tablet, which manufacturers can purchase directly from Eton or buy off the shelf. A standard PC host can be used to store and report all the data collected and can be integrated with third-party reporting, payroll or enterprise resource planning (ERP) systems. Plus, Eton is introducing the ETONnote with a pay-per-use plan based on the number of workers who use the system daily.

“While the visibility, control and other benefits of these systems have been proven over many years, ETONnote is making real-time shop floor affordable for all manufacturers by eliminating the high costs and lengthy implementation times associated with wired networks and proprietary workplace terminals,” said Per Bringle, president of Eton Support U.S., in a statement. “We are also changing the game with a dynamic pay-per-use plan that charges only $1 each for the precise number of workers that use the system on a day-by-day basis.”

For more information, visit www.etonsystems.com.