The/Studio’s On-Demand Platform Wants to Reduce Turnaround Time for Apparel

On-Demand Efficiency

As of Thursday, January 3, 2019

Now in its fifth year, Los Angeles–based The/Studio is gaining momentum by streamlining apparel production with its product-development and on-demand manufacturing platform.

While the company doesn’t manufacture apparel, its resources include a team of designers, 400 factories as well as offices in China, Romania, the Philippines and San Francisco. The brand’s approach to fashion sourcing was an attractive enticement earlier this year for investors, including Ignition Partners, FJ Labs, VTF, WTI, Firebolt Ventures and Interplay Ventures, which supported The/Studio’s Series A round of funding, which totaled $11 million.

“Everyone recognizes that retail is changing,” founder and Chief Executive Officer Joseph Heller said. “This requires rethinking the supply chain and manufacturing. You need to create greater accessibility to supply-chain manufacturing and a platform where lead times shrink and there are lower minimum-order requirements.”

Through improving communication between brands and factories, Heller sees an opportunity to more efficiently manage manufacturing and help brands successfully navigate the new retail landscape, which seems to be forever changing.

Citing the industry’s reputation for overproducing goods—where 30 percent to 40 percent of items are discounted—Heller feels the fashion industry can’t survive if it continues to operate as it has in the past.

“If you can manufacture in smaller batches with quicker turnaround time, you can behave more like a software company,” he said. “If you look at Amazon, they run thousands of tests every day, and those tests make them more efficient. We believe if brands order 500 pieces, they can test those ideas.”

Heller is providing new solutions to solve old apparel-production issues as emerging brands search for options to limit manufacturing costs and larger brands examine eliminating wasteful production along the supply chain.

“We believe there are a lot of really good factories out there that know how to produce products,” Heller said. “We don’t need to reinvent the manufacturing process. We need to reinvent transparency, accountability and communication.”

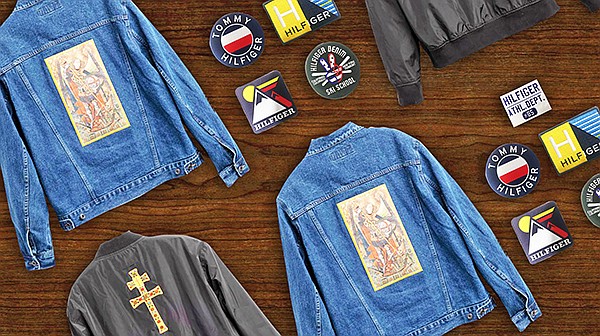

Since its 2013 launch, The/Studio has grown into a business in downtown Los Angeles’ Little Tokyo district and has worked with 100,000 clients through its platform and created more than 32 million products. Among its customers are major companies that include BLVD, Calvin Klein, Disney, Mountain, Nike, Phluid, Rockets of Awesome, Tommy Hilfiger and Urban Outfitters.

“We onboard factories to our platform and train them on how we expect them to operate,” Heller explained. “We train them to understand metrics such as on-time delivery, redos and refunds—things that factories don’t really measure today, especially the smaller factories.”

Building upon his manufacturing experience, which included 10 years learning the business in China, Heller examined how lack of communication between brands and factories slowed the manufacturing process.

“We’ve built a two-sided marketplace,” he said. “We have tools on the customer side including a dashboard, communication tool and tracking tool so that the customer can manage the entire relationship with the factory.”

Through The/Studio’s cloud-based system, factories are provided information that has been streamlined into a standard process. Rather than forcing factories to work with different tech packs from a variety of clients, The/Studio examines orders from customers and translates them into its standard blueprint.

“We also built a cloud-based solution for the factory that informs how the factory works with our order, so there is information and tools on how to deliver the product on time and how to manage the order,” Heller explained.

As a graphic designer for the gaming and anime company NIS America, Chelsea Beaubien knows a lot about satisfying the demands of her audience, which comprises male and female gamers and anime enthusiasts ages 15 to 34. To support the marketing push for the company’s SNK Heroine and the 15th anniversary of its Disgaea Series, Beaubien searched for a new apparel-manufacturing resource following a bad experience with a previous partner.

“We would email for an update, and they would take weeks to respond,” she said of NIS America’s former manufacturing resource. “The main guy we would communicate with would forget our order or change it to products we weren’t asking for. It was disheartening when our designs were changed and we weren’t making deadlines.”

Searching for a resource that would be able to accommodate a short timeline yet provide quality, limited-edition goods for devoted fans, Beaubien turned to The/Studio. She was pleasantly surprised when NIS America received a quality sample only one week after her company submitted its design. After NIS America placed its order, the pins, wristbands and caps—priced from $0.84 to $14.32 per unit—arrived at the company’s warehouse within 30 days.

“They were able to do both large and small orders,” she said when discussing her experience with The/Studio. “We weren’t sure how many we would be producing, so it was nice to know there was flexibility regarding what we could order.”

Through its pricing calculator, The/Studio provides transparent calculations to customers, with the lowest-priced order costing $500 and the highest to date being a $400,000 project. In 2019, the company will begin to offer a tier-based subscription service. Acting as an agent for freelance designers, while providing services to brands who require specialized services, The/Studio will roll out this latest offering during the second or third quarter of 2019.

“We’re creating a marketplace for third-party designers, where our customers can pay a subscription to us,” Heller said. “Our designers can submit designs to brands on a monthly basis, and those brands can take those designs and manufacture on demand with our platform.”

While Heller is still working on the numbers, he envisions starting with a low-commitment trial basis. Once the details of the service have been finalized, he estimates the low-end annual subscription costing will be $25,000 and the highest-level commitment will be several hundred thousand dollars.