Thwarting Counterfeiters With Technology

Technology executives think they’ve come up with the ultimate answer to the age-old fashion industry question “Is it real or fake?” Their answer: phosphors. Phosphors are organic dustlike materials that emit light when reacting to infrared beams, and tech companies have found a way to integrate these materials into threads and yarns to help fight against counterfeits.

A small handful of tech companies are working with label and tag makers and are targeting apparel manufacturers, government agencies and trade groups to market these products as a more efficient and cost-effective way to guard against counterfeiters, whose efforts to take advantage of well-known brands have become a $200 billion industry in the United States.

The apparel industry and others have been using holograms and ultraviolet technology to authenticate goods, but marketers such as Dan Barnett of Bellevue, Wash.-based Stardust Technologies Inc. say these methods are either too costly or unreliable compared to phosphors.

The material Barnett has brought to the market caps nearly a decade of research and development that originated in Cold War–era Russia of all places. Russian physicist Edward Talyansky initially developed the ceramic-based material for use in the Soviet military, but he sought more commercially appealing uses after immigrating to the United States in the early ’90s. Talyansky first launched his own firm in Portland, Ore., with son Vitaly, but the two have recently joined forces with Barnett. The new company is targeting such mass-market industries as apparel, tobacco, electronics, corporate identification and security systems.

The secret of Stardust’s material is in its light-producing qualities, which show up with the aid of an infrared scanning device about the size of a pen. Counterfeiters can’t replicate the technology because it’s too expensive, said Barnett. But it’s substantially lower in price than holograms and other methods.

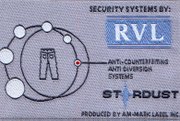

The technology has caught the attention of some of the largest tag and label suppliers, including Paxar and RVL. Stardust is looking at direct sales to apparel companies as well. The product doesn’t wash out and can stand temperatures up to 1500 degrees.

Barnett and Vitaly Talyansky see the product becoming important in the customs and logistics process as well as for clothing producers verifying product upon landing. The scanners can work through boxes and lightweight materials. The company is also looking to bring an audio-response version to the market.

Talyansky has had the product trade secret protected and said no one even knows where the material is produced.

As the counterfeiting business grows to $1.7 trillion globally, Barnett said apparel makers can’t even afford to trust their own subcontractors. According to the Federal Bureau of Investigation, most bogus goods come from China, Taiwan and Malaysia. Mexico has also been a frequent source.

The targets in the apparel business are the big brands such as Nike, DKNY and Tommy Hilfiger. Barnett estimated that up to 80 percent of NFL licensed goods sold are counterfeit.

“The Internet has been a big boon for counterfeiters, and even at the factory level there’s a lot of ’one for me, two for you’ negotiating going on,” he said.

So far, the demand for phosphors detection devices is small, though giant 3M Corp. has brought a product to the market as has the United Kingdom-based firm D&A Tech. Barnett thinks Stardust has the advantage with more colors and smaller particles. The company recently completed a $2.6 million round in financing and is in line for another $7.5 million.