Producing Garments at the Speed of Light

The beams of bright light used in body scanning technology are no longer the sole domain of research institutions and movie studios. They are becoming important tools for the apparel industry.

As costs come down, apparel manufacturers are tapping into laser technology to help them do everything from creating made-to-measure clothing to cloning fit models to producing the perfect fashion shoot. The aim is to get products to market faster as well as improve quality control.

Technology providers have commercialized scanning technology to produce scanning booths that can be built in a small area of a store or studio. The scanners measure the human form in a matter of seconds to specifications that are within a millimeter of being exact. In the past, companies have used body scanners primarily for research, but some retailers, including Brooks Brothers in New York and Selfridges & Co. in the United Kingdom, are now using scanners to conduct on-the-spot digital tailoring for custom clothing. The new generation of body scanners is smaller, faster and less expensive.

Cary, N.C.–based [TC]2 ’s new NX12 scanner measures 5 feet by 9 feet and costs $40,000. Other scanner manufacturers include Monterey, Calif.–based Cyberware Inc. and German company Human Solutions GmbH, which has U.S. offices in Troy, Mich.

Some machines use white light, and others use laser light. Some capture “cloud data,” or digitized data, better than others, said Ilona Foyer, chief executive officer of Malibu, Calif.–based technology company Shapely Shadow Inc.

[TC]2 used its scanners to compile measurements of Americans for the recent SizeUSA national survey. The company is marketing the scanner as well as the survey data. SizeUSA meetings were held at the Fashion Institute of Design & Merchandising and JCPenney stores in Los Angeles, as well as at JCPenney stores in 12 other major cities. For [TC]2 and its clients, the survey provided insight into how America’s sizing demographic is changing.

With growing ethnic and aging populations in the United States, fitting the average consumer is becoming more difficult, said Jim Lovejoy, director of the survey.

“What should be a women’s size 10 is now a size 8,” Lovejoy said. “As you get older, you get bigger. The best-selling clothes are more forgiving.”

Lovejoy said the apparel industry has reacted by producing more stretch fabrics and knits. Providing custom tailoring has helped some gain an edge. Brooks Brothers and Selfridges have installed body scanners in some stores to provide custom-tailoring services that would be difficult to match using traditional methods.

Paris-based Lectra is using the machines in its campaign for mass customization in Korea and China.

Tolland, Conn.–based Gerber Technology is participating in a government project in China using body scanners and Gerber’s Accumark CAD system to train upcoming designers.

Scanners such as [TC]2’s provide 800,000 points of data and can be outfitted with software that produces DXF files, which can be used for CAD and cutting systems. The result is that custom garments can be made within a couple of weeks.

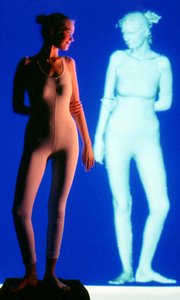

Commercial applications for scanning technology are growing, especially on the West Coast. Southern California companies, including Shapely Shadow and Los Angeles– based Tukatech Inc., have employed body scanners that use mathematical measurements to create near-perfect cyber dress forms. Fit models are scanned and eventually “cloned” into dress forms using the data provided by the scanner. Overseas contractors can use the forms to fit samples and speed up the development process because of the accuracy of the measurements. Shapely Shadow and Tukatech have developed forms using silicon and urethanebased composites that are more lifelike in appearance and feel than traditional dress forms.

“You can slip on a pair of tight jeans with no problem. You can’t do that with a linen form,” said Paul Clarke, vice president of operations for Tukatech. “Someone like Warnaco may have 40, 50 or 60 vendors, so you can’t send a fit model to all those places.”

Clarke said clients can also customize forms to replicate the ripples of muscles or create cleavage for swimwear and innerwear. Hollywood has used the technology to develop animated characters and special effects and to clone actors for costume fittings.

Scanner-created measurements are far superior to manual measurements because they can measure shape, which is vital to apparel manufacturing, according to Foyer.

“The older body is more curved,” Foyer said. “You can’t confuse a junior fit with a missy fit. You can’t get nearly the accuracy of a scanner with manual measurements.”

Laser-assisted fashion photography

Scanning technology is also being brought into fashion photography to fine-tune editorials and advertisements. San Diego fashion photographer Greg Passmore said he is using infrared laser scanners on his shoots to capture the exact geometry of models and sets, creating “deep” images that can be altered to prevent expensive re-shoots and reduce costs for clients and himself. “Sometimes you get clients who come back and want a different background plate,” Passmore said. “Oftentimes the model isn’t available, so you can’t do a re-shoot.”

Pixels are augmented with distances and angles to create a flexible and powerful postprocessing capability, Passmore explained. Calculations automatically produce a database of the angles between the subject and the camera and stage lights, as well as critical depth information. The resulting “deep” photograph can undergo radical relighting well after the shoot has concluded.

Architects have been using the technology during renovation projects to identify details that traditional lighting methods may miss. In fashion, using infrared light helps pick up the blacks that traditional red lasers cannot identify, Passmore said.

Scanner manufacturers expect that as the technology improves, it will gain momentum in the mainstream apparel business. Consultant Warren Hartenstine of Havre de Grace, Md.–based Tower Associates LLC has been working with companies, such as Hong Kong–based TPC (HK) Ltd. and D-Three Software Inc. in Maine, that have been making in-roads in streamlining CAD data for various applications, including scanning.