Made in California: A Special Report

Even as the number of manufacturers producing clothing and accessories overseas grows, many U.S. companies still choose to produce domestically. California ranks high among production locales, with Los Angeles considered the premium-denim capital and home to many established and emerging contemporary brands. Obvious reasons for West Coast production are logistics, as well as quality control, shorter turnaround times, and contributing to the U.S. economy.

We spoke with a variety of contemporary apparel companies, denim brands, and accessory designers from the United Kingdom to San Francisco, New York to Los Angeles, to explore the advantages (and disadvantages) of producing in California.

575 Denim

Since October of 2004, 575 Denim has been produced in Los Angeles. Owner Frank Mechaly cites quality control as one of the many advantages of producing in California. “I’m personally behind every single part of the process to make sure that the product is meeting our standards,” says Mechaly. “We notice that overseas production quality has improved, not only in the quality of their denims but in the wash techniques as well. We are not opposed to work overseas, but when you really get down to the digits, it’s as costly overseas as it is in California.”

Advantages: “Shorter production time. It’s more hands-on and you get to see your product at every stage of production. It is easier to manufacture in California, as long as you have the right contractors.”

Quantities and sales: 6,000 units per week, $26 million annually

www.575denim.com American Apparel

Launched in South Carolina in 1997, American Apparel moved production and company headquarters to Los Angeles in 1999. With an in-house production facility downtown, American Apparel boasts the ability to produce in a matter of days what typically takes weeks or months. “Having the complete operation in-house allows ’real’ visibility that many other companies do not have the luxury of,” says Vice President of Operations Marty Bailey.

Advantages: “Quality assurance. Product design and fit adjustments are made immediately, minimizing inventories of product that do not pass the buck.”

Disadvantages: “Much of the supply chain has followed the offshore exodus of manufacturing. Sometimes this can delay our process, simply waiting on garment accessories.”

Quantities: 1 million pieces per week

C&C California

Launched in 2003, C&C California produces all of its knitwear in Southern California. As the name implies, this aspect is part of the culture and identity of the brand and the majority of the fabric sourced is also made in California. Though the line has evolved to include wovens and cashmere pieces that are produced in China, the company intends to keep most of the production in the United States. “We will always produce the majority of our line here in Southern California, no matter the size of C&C. It’s part of our brand,” says Vice President Stephen Cox.

Advantages: “Monitoring production closely. We have established quick turnaround and lead times with our key manufacturing base, which is important in the contemporary zone.”

www.candccalifornia.comChip & Pepper

Los Angeles label Chip & Pepper has produced in Los Angeles since the brand’s launch. One hundred percent of the denim is produced in an off-site facility in Los Angeles, while samples are produced in-house. The line has evolved to include sportswear and tees, of which 80 percent are produced in Los Angeles. “Because we are headquartered here, it’s easier for us to personally be involved in quality control and monitor washes and fits, plus it is safe to keep development close to home in such a competitive market,” says co-owner Chip Foster. “Also, as two Canadians who still pinch themselves daily at how far we have come in this industry, it is a personal success to be able to say our product is not only made in the U.S.A. but in L.A. specifically.”

Advantages: “The best denim facilities are here in L.A., and you can’t even compare quality of the product produced here versus elsewhere. Washing is a key factor in premium denim, and the best wash houses are right here,” says Pepper Foster.

www.chipandpepper.comDaftbird

Daftbird designer and owner Josh Christopher produces his contemporary T-shirt line in Los Angeles and says that having more creative control is the biggest advantage to producing in California. “I was led to manufacture in L.A. by a referral to an amazing production facility,” says Christopher.

www.daftbird.comDeere Colhoun

Prior to the Spring 2007 launch of Deere Colhoun, designer Lindsey Colhoun experienced overseas manufacturing as the designer of another handbag company. Deere Colhoun is based in Malibu, and all production and manufacturing is done with an independent contractor in Los Angeles. “I wanted to use local manufacturing to support ’Made in the U.S.A.,’” says Colhoun. “I think it’s important to support local business.” Deere Colhoun also uses California companies to source its fabrics and hardware, which come from a variety of locales, including Italy and Japan.

Advantages: “Quality control and much quicker production time, which also facilitates re-orders.”

www.deerecolhoun.comEndymion Leather

Los Angeles designers Arianne Tunney and Kerry Johnston launched their luxury handbag line in 2006. “L.A. seems to be really growing in its ability to satisfy all needs in manufacturing even in the very high-end market,” says Tunney. “Our manufacturers are close, making it easy to be really hands-on in every step of the process, which really makes for a more perfect product.” The company only uses Italian leather, but it is sourced from companies in California, as are the linings used in the bags.

Advantages: “The main advantage of manufacturing in California is quality control. As owners, we have direct constant contact with our manufacturers,” says Johnston.

www.endymionleather.comGolden Cast

Kevin Lee, head designer of contemporary label Golden Cast, has been producing the line in California since the launch four years ago.

Advantages: “Quantity. We can do specialty styles that wouldn’t have made the minimums of overseas factories. Fashion-forward styles aren’t necessarily top sellers for us, but they play a major role. Those styles are what defines the collection and hopefully creates a buzz. That’s important for a young, independent line like ours. Another benefit would be time. We personally try to keep the sales window open for as long as we can. The faster turnaround time helps us stay more adaptable to market changes and lets us refine what we produce. It’s so crucial to ship on time, and if there are mistakes in production we can correct it.”

Disadvantages: “Sometimes the quality isn’t as high as we’d like. Quality and smoother production definitely costs more. Contractors can find easier work to do that doesn’t require a highly skilled worker. Also, it’s very difficult to find a contractor that is willing to do more-complex styles at lower quantities. Our contractors definitely prefer quantity to complexity.”

www.goldencast.comHeidi Merrick

Dress designer Heidi Merrick is among the many emerging designers based in Los Angeles offering quality and innovation in small quantities. “I intend to keep production in Los Angeles,” says Merrick. “I have a higher price point, so I can. But my goal for next year is to do a good percentage of the line in-house. It’s a quality issue, and haggling gets exhausting.”

Advantages: “The ability to oversee every aspect. There are always mistakes and there are always changes to be made.”

www.heidimerrick.comJ Brand

Jeff Rudes and Susie Crippen launched J Brand in 2005 and chose Los Angeles as home base for all aspects of the brand. “Los Angeles is one of the leaders in premium-denim production in the world,” says Rudes. “We have some of the best sewing factories and laundries in the country here. We produce all of our denim in our own facility, in our corporate building. Our sewing lines are exclusive to J Brand only.”

Advantages: “For premium denim, fast turn, short runs, new styles to market quickly, and quality that matches the best needle in the world.”

www.jbrandjeans.comLoFli

United Kingdom–based premium-denim brand LoFli moved production from Italy to Los Angeles in 2005. LoFli now produces 100 percent of the line in Los Angeles. “We have full-time quality-control reps on every production run from start to finish. Without quality-control supervision and attention to detail at every stage, one’s virtually guaranteed of facing imperfect quality issues—which cumulatively get even worse—frequent technical mistakes, and a generally inferior adherence to the strict quality standards that are necessary when shipping a premium product,” explains designer/cretive Director Sheel Khemka.

Advantages: “There is an abundance of local sewing contractors, embroidery facilities, and wash houses that are specifically geared to produce denim to the strict quality standards required for a premium product. The other advantage is an ethical one. Stringent California laws mean that local contractors adhere to the minimum wage, worker’s compensation, and all the other employment regulations that exist in California. This means we can rest assured that the workers who make our garments are well looked after.”

Disadvantage: “Cost. Albeit this is a sacrifice that has to be made in exchange for consistent and good quality product and decent working conditions for those employed to manufacture our garments.”

Quantities and sales: “During 2006, we shipped just over $1 million wholesale, which amounts to just over 12,000 pairs of jeans. Going forward for 2007, our projections estimate wholesale revenue between $3 million and $5 million, which is equivalent to 40,000 to 50,000 pairs of jeans.”

www.lofli.comMike & Chris

Husband-and-wife team Mike and Christine Gonzales have manufactured their line, Mike&Chris, in California from day one. Independent contractors in Los Angeles produce the collection.

Advantages: “Definitely the control from a quality standpoint, delivery, and overall production process.”

Disadvantages: “There aren’t as many factories as there used to be, considering the boom to go overseas. It hurt a lot of factories, and they ultimately had to shut down, leaving those of us who produce here with slim pickings.”

www.mikeandchris.comNot Your Daughters Jeans

Since 2003, Not Your Daughters Jeans has produced in California using independent contractors. Fabric and hardware for the jeans are imported.

Advantages: “Faster turn, more control, smaller quantities, keep America working,” says CEO George Rudes.

Quantities and sales: “For 2007, we will produce 1.5 million, $55 million in sales.”

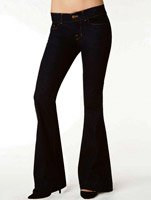

www.tummytuckjeans.com Paige Premium Denim

Paige Adams-Geller has produced her premium denim in Los Angeles since the brand launched in July 2004. All denim (women’s and men’s) is manufactured in an off-site facility, while a percentage of the lifestyle collection is manufactured outside of California. “Unlike in accessories, it is important to have constant control over fit throughout the entire manufacturing process with denim,” says Adams-Geller.

Advantages: “More control over fit and final product. We can easily make fit modifications. Because the facilities are in such close proximity to design headquarters, our turnaround time is much quicker. Since California is the denim epicenter, we have the top wash houses and manufacturing facilities in the industry at our fingertips. And last but not least, we appreciate contributing to the U.S. economy.”

Disadvantages: “The disadvantages are few, but if I had to say one, I would say cost. You pay more for the accuracy of the product, but like the old adage goes: You get what you pay for.”

www.paigepremiumdenim.comPuella

Co-owners Sarah Cius and Sarah Woodward Becker have produced their line Puella in California since the company launched four years ago. “Some companies would say the prices are less expensive to produce overseas,” says Cius. “For what we currently are designing and making here, we have found that they are comparable. The only disadvantages are the limitations on what we can make, for example, sweaters.”

Advantages: “Throughout the production process, many unexpected problems can come up. Because all of our vendors are local, we can work together to correct problems quickly and ship our orders on time. Also, we can keep our deliveries open longer.”

Quantities: About 60,000 units

Rachel Pally

In a short time, Los Angeles designer Rachel Pally has become the queen of jersey fabrications. The line has been produced in Los Angeles since its inception, and Pally intends to keep it that way. “It is important to me, personally and politically, to produce in Los Angeles. This is my city and my local economy, and it’s important that I contribute,” says Pally. In addition, she says, “All of my jersey fabric is milled locally.” Pally’s Fall cashmere group, however, is being made in China, “simply because there are no local alternatives,” Pally says.

Advantages: “In addition to supporting the local economy, having production here also allows me to keep a close eye on the process to ensure quality.”

www.rachelpally.comRebecca Ciccio

Since the brand launched in September of 2005, Rebecca Ciccio has produced her entire line at an off-site independent contractor in San Francisco. “Although Los Angeles has more options in terms of production companies, we really wanted to keep everything local so that we could be very involved with all aspects of manufacturing, from design to production,” she explains.

Advantages: “I love supporting local businesses. It also provides an advantage for us as we are able to execute our own production quality control, as well as provide shorter lead times to our customers.”

Disadvantages: “Our labor is very costly, but the high-quality end result is well worth it and appreciated by our customers.”

Rebecca Minkoff

New York–based designer Rebecca Minkoff recently decided to move part of her production to Los Angeles. The decision stemmed from her goal of keeping production in the United States. Beginning with the Spring 2008 collection, Minkoff hopes to have 75 percent of the line manufactured in Los Angeles. “I intend to keep production in the U.S. as long as I can,” says Minkoff.

www.rebeccaminkoff.comRed Engine

Red Engine jeans launched six years ago, and the entire line is developed, and manufactured in Los Angeles. “We are constantly in production and carry inventory, and we ship every day, not just by seasonal delivery dates,” says owner Jim Boldes. “Our production model creates a situation that our buyers love, because they can get Red Engine shipments immediately most of the time; we can often ship an order the day we get it.”

Advantages: “Our operations offices are in the same building as our manufacturing, which allows us to keep a close eye on issues of quality, and allows us to deal with issues the moment they arise. It allows us to be more hands-on from conception and design to final production.”

www.redenginejeans.comTart Collections

Tart Sportswear has been produced in California since its inception six years ago. For Fall 2007, 60 percent of the goods will be produced in California (and 90 percent of the fabric sourced in Los Angeles) while the Sweet Tart, Lemon Tart, and Tart Intimates collections are produced overseas. With a business that has more than doubled since last year, Jamie Finegold, owner, JD Fine & Co., partners with outside contractors for production. “This gives us the ability to expand and contract as quickly as necessary,” he explains. “It also enables us to place goods with contractors that specialize in specific fabrications. We will always have some production in California, due to the great advantages,” he continues. “However, if the opportunity arises and the quality is good, we would definitely consider producing some sportswear items overseas.”

Advantages: “The quick turn and the ability to oversee quality every step of the process. Also, the ability to re-cut a group that may be selling really well.”

www.tartcollections.comWebster

An independent contractor in Los Angeles produces designer Alexia Landeau’s contemporary line, Webster.

Advantages: “It allows a more hands-on approach to production,” says Landeau. “Outsourcing can be ethically challenging on many different levels.”

Disadvantages: “Limited fabric sources unless you import or ship from New York, high sewing costs, and production costs.”