Customization for the Masses

It is no longer an off-the-rack-world, with computer programs making custom fashions available to all

Imagine designing your dream wardrobe—with fabrics, styles and details individually selected by you and each item tailor-made to fit every nuance of your body. Is this a luxury only the super-rich can afford? No. The technology exists now and is being used with increasing frequency at every level of the apparel industry, from professional couture houses to the home sewer/designer.

Mass customization is the use of computer-aided design (CAD) techniques in concert with flexible computer-aided manufacturing (CAM) systems, which allow users to individualize products while keeping price points low.

Customer-influenced design allows buyers to put their own style stamp on items such as cars, clothes and furniture in order to have a product wholly unique to the individual’s wants and needs.

This trend in the apparel industry has been around for a while. In 2001, Lands’ End introduced its personalization program on its Web site, allowing customers to order made-to-measure items to their chosen specifications under the Custom Clothing option on www.landsend.com. A customer can pick the color of denim as well as the jeans’ rise, fit, front and back pocket design, and leg style. The customer then fills out a detailed measurement and body-shape cart, with fit preferences, and the order is complete. Lands’ End keeps these dimensions on file for additional and future orders. Pricing for a pair of women’s custom Lands’ End jeans starts at $70. The process takes three to five weeks from order to delivery.

Now, industry leaders such as New York–based Opti- Tex USA; Kowloon, Hong Kong–based PAD System Technologies; and Paris–based Lectra are reaching new heights in mass customization technology.

Do-it-yourself styling

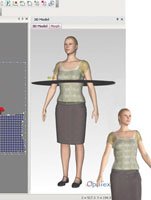

Yoram Burg, president of OptiTex USA, presented the company’s revolutionary made-to-measure utility at the World Conference on Mass Customization and Personalization in Montreal last October. OptiTex offers multiple versions of its signature design software, which utilizes 3D and 2D virtual models to illustrate every distinction of a computer-generated garment.

“Our made-to-measure 3D visualization software allows previously flat patterns to be displayed on adjustable parametric mannequins,” Burg says. “Now designers can scrutinize every detail of the garment, including fabric, drape, fit, movement and style.”

OptiTex recently partnered with Bernina USA to release My Label 3D Fashion Pattern Software, which allows a home sewer or designer to create virtual designs. Once the item is perfected on screen, the program generates custom patterns.

My Label comes with 20 standard pattern options that users can alter at will. Users can employ 44 separate body measurements to create a 3D avatar with those exact dimensions.

A customer can choose from a plethora of fabrics, textures and colors; further customize the item with buttons, stitching and other decorative elements; and then learn how each piece will look and move on her body—before the first cut is ever made.

Brides.com (www.brides.com) has partnered with OptiTex to create the site’s Custom Fit Tool, which helps a bride find a style of dress that flatters her body type.

“The tool has been extremely well received and has already become an integral part of our Web site, creating very high traffic volume for us, as well,” says Susan Rerat, vice president of Brides.com.

“This technology is going to become more accessible across the board,” Burg says. “OptiTex is the only CAD vendor that is a Microsoft partner and that is fully compatible with all CAD hardware and software. In the past, CAD providers wanted you to use only their systems, and, if you weren’t compatible, you were out of luck.”

So what modifications can consumers expect to see in the future?

“Refining sizes and creating in shorter time durations. The two latest buzzwords are ’global fit’ and ’cycle time reduction,’” Burg says.

Global fit is a lengthy process to develop better, more accurate garments that will fit the average person, Burg says. And cycle time reduction is about generating faster turnaround in all phases of the process.

One of the best ways to do this is by cutting back on samples, which is also a result of better product lifecycle management processes. “In the past, a mid-size company might make 200 samples a season, and, of those, 30 would make it to market,” Burg explains. “Now, half of those can be made virtually, and those same 30 garments will make it to market in half the time.”

Thinking inside the box

PAD System Technologies is another developer of high-performance CAD/ CAM systems with complete tools for designing, grading and pattern-making. Kristine Gloviak, PAD’s vice president of implementation, became an aficionado of mass customization 30 years ago, when she was a graphic designer just breaking into the apparel industry.

“My frustration was with how the industry oversimplified the human body—it is an amoeba, a thumbprint, and no two are exactly alike,” Gloviak says.

She began researching the principles of what would become mass customization and studied ways to implement the theories on a practical level. Of course, financial viability was a large hurdle. Now, according to Gloviak, a breakthrough solution is on the horizon: comprehensive body scanning.

“The new scanners will not be like those that came out seven or eight years ago, which were mostly smoke and mirrors,” Gloviak says. “Low-cost body scanners are currently in development, and , in the not-too-distant future, there should be one in every shopping center, like ATMs. Once you’re scanned, your dimensions will be saved on a card, and you can then take it to any store to find your best fit.”

But Gloviak adds: “Though 3D systems are very intriguing, they have limits. They can’t simulate every fabric. For instance, silk is always going to move and drape differently.”

The price has to be right

Lectra is another major player in mass customization on the worldwide stage, offering apparel industry hardware and software solutions across the board, including 3D prototyping, design, cutorder planning, made-to-measure and marker making.

“There are many, many mass customization possibilities in fashion,” says Hari Kenkare, schools partnership manager for Lectra. “In automotive, for instance, the base product is static, and only the surface details are customizable, although that is also likely to change very soon. Car buyers will be able to choose not just the fabric and color of their interior, but the shape of their seats, the design of the dash, etc. In fashion, there are already infinite possibilities to work with.”

For fashion designers and apparel makers who are looking to create their fashions on a storyboard and then view them in a virtual setting, Lectra’s customization solutions include Kaledo Style, a virtual software that allows fashion designers to draft their designs in a two-dimensional format and then view those designs in a three-dimensional storyboard program. More important, the software’s design tools and capabilities enable designers to define styles, create products and test product variations easily.

Kaledo Style’s features not only integrate design trends, color palettes, fabrics and motifs, but also seamlessly interface with the production end. The software has the capability of allowing the design, merchandising, sourcing and manufacturing entities as well as other participants in the product lifecycle to collaborate as a collective. Each participant in the product lifecycle can view a collection from his or her own viewpoint. For example, knit managers can view the knits only, while manufacturers can view specifications or technical data.

According to Jerry Inman, vice president of marketing, Kaledo Style allows designers to create storyboards and then modify the drawings in near real time in response to feedback from merchandisers and planners. This results in faster designing; greater freedom to experiment with colors, patterns and fabrics; and faster reactivity to modifications.

What’s more, the software’s virtual products eliminate the need to redraw items manually each time a change is made, while ensuring that everyone has access to the updated information. Instead of repeating all of the design steps in order to make modifications, designers can make and present changes immediately.

“When you change one element in a design, it is recorded with all compatible elements, and every other element changes accordingly,” Inman says. “Kaledo Style reduces costs and the number of meetings and samples throughout the design process.”

In the life of almost every technology, there is a time when it evolves from being an expensive novelty to serving as a business-savvy, cost-cutting tool. Each company, like each consumer, has to decide when that time has come.

The make or break with any technology is the price point, says Kenkare. “The premium mark up for consumers who use the customization features is usually around 17 percent, he says, adding, “If you can keep it within that range without going over, you have a highly marketable product.”