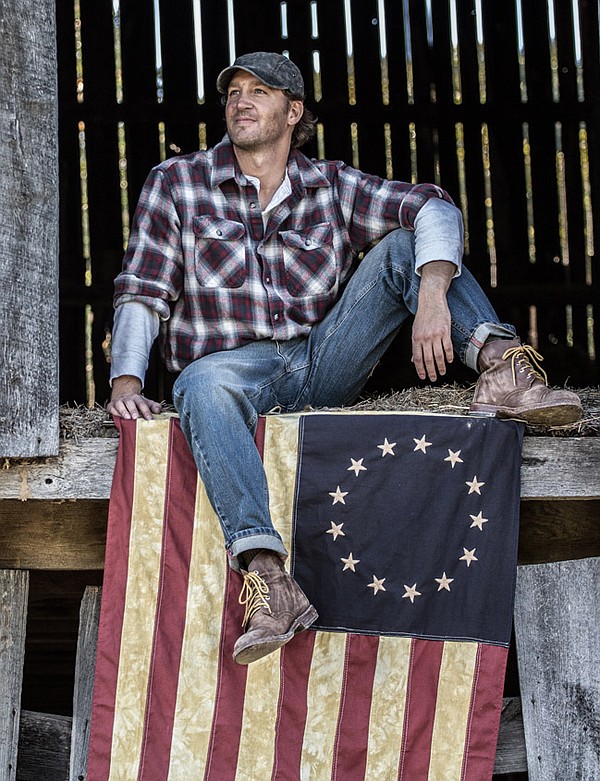

DIAMOND GUSSET

American-Made Denim For Nearly 30 Years

After 28 years in business, Diamond Gusset jeans owner and co-founder David Hall says there is more happening with the Bon Aqua, Tenn.–based company than ever before. Diamond Gusset, which has carved out a successful niche by always maintaining a 100 percent U.S.-based supply chain, is poised for record growth this year.

A U.S. supply chain allows Diamond Gusset to maintain quality control better than if its suppliers were located offshore, Hall says. Most of the company’s suppliers are located within just a few hours of Bon Aqua, which is about an hour west of Nashville. While Diamond Gusset employs fewer than 20 people, Hall says the work it provides through its supply chain helps keep at least 60 more people employed.

“A lot of jeans today are sewn offshore with a lack of quality control, resulting in ill-fitting jeans,” Hall said. “You can go into a chain or box store and buy six pairs and every one will fit differently. By sewing with the same sewers in the same factory, we have top-notch quality control. Every pair we make will fit the same, and that has been a big advantage for us over the years.”

Hall, along with his cousin, founded Diamond Gusset in Nashville in 1987. Hall had been a salesman for Levi’s and Lee’s jeans. He says the idea for the gusset, which is sewn into the crotch of the jeans and relieves stress by distributing pressure to four points, came from karate uniforms. The durability of the jeans, along with the made in the U.S. aspect, has created a loyal customer base for the company through the years.

Southeast supply chain

Diamond Gusset jeans are sewn at A&S Clothing, a small company in Blue Ridge, Ga. Hall says his company accounts for about 75 percent of A&S Clothing’s business. He says their employees are like family and know Diamond Gusset’s products intimately.

“We have done it so long, it’s gotten quite easy,” Hall said. “We know their sewers by name, and we have a good relationship there.”

Hall sources the pocketing for his jeans from Mount Vernon Mills, which has plants throughout the Southeast. Hardware comes from a company in Kentucky. From Blue Ridge, the jeans are sent to Joro Enterprises, a finishing plant in Winder, Ga. There, they go through all of the various finishing processes, including stone washing and sandblasting. The jeans are inspected, pressed and ticketed and then sent to company headquarters in Bon Aqua. They are then sent to retail stores in Bon Aqua and Lynchburg, Tenn., and to the company’s shipping center at its headquarters, which handles its Internet business.

The Lynchburg store opened in 2012. The Jack Daniels Distillery, which dominates the town, provided the retail space and paved the way for Diamond Gusset to open in Lynchburg. Hall hopes to eventually open a third store in Blue Ridge, but he doesn’t anticipate opening a lot of stores. “We don’t want to be a 100-store chain,” he said.

The key segment of Diamond Gusset’s supply chain will change in January when its longtime denim supplier, Littlefield, Texas–based American Cotton Growers, closes its denim plant. ACG has supplied denim to Diamond Gusset for many years. Hall says he plans to source denim from the remaining three U.S. denim manufacturers—Mount Vernon, Cone Mills and Denim North America. Diamond Gusset’s jeans are known for their durability, with many styles using top-quality 14.5-ounce heavyweight coarse denim, so re-establishing a steady denim supply is a priority for Hall.

Brand building while keeping core

Other changes are afoot at Diamond Gusset as the jeans maker prepares to expand and broaden its product line. Over the past year, Hall has bolstered his management team, hiring a vice president and designer, both well experienced in the retail business.

“We are in the middle of a great big transition,” Hall said. “We’ve been developing a lot of new products over the past nine months. We have new products, new logos and an improved Diamond Gusset. We’re not changing anything related to quality, and we will always continue with our basics.”

In recent years, Diamond Gusset branched into co-branding. The first foray was with Paul Teutel of the TV show “Orange County Choppers.” That resulted in development of the “Defender,” a motorcycle jean made with a percentage of Kevlar to protect skin in the event of an accident. More recently, the company has aligned itself with country-music singer Larry Gatlin for a line of dress jeans and western yoke blazers. The line is called the Legend Series and will be produced by the Sewell Co. in Bremen, Ga.

The fourth quarter is traditionally Diamond Gusset’s peak season.

“It will be a good fourth quarter for us,” Hall said. “I can confidently say we will have a record fourth quarter.”