3-D Tools Speed Up Production for Apparel Companies

Emerging 3-D technology isn’t just improving visuals for garment producers. It’s helping them get products to market faster.

Recent improvements have validated 3-D. The technology is faster, more functional and more visual than ever before. Whether used on a computer screen to help patternmakers visualize their creations or as the final product on a dress form, 3-D is helping apparel companies substantially cut their production times.

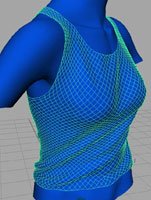

When using 3-D for patternmaking, a designer can drape garments over a digital image, rotate them, zoom in and visualize how the piece will look.

“It can cut your sample process down hellip; from five [iterations] to two,” said Kent Parajon, the Los Angeles–based sales manager for Israeli company Browzwear.

When using 3-D for merchandising, retailers can visualize how their departments will look with clothes they have not yet purchased. Designers can also put 3-D to work on storyboards, giving the product development team a view into the future.

“3-D technology is here to stay,” said Yoram Burg, president of New York–based OptiTex USA Inc., which markets CAD software and 3D Runway, an application that runs seamlessly with the company’s PDS (pattern design system) and other systems.

“[3-D] is allowing companies to communicate with overseas factories without having them physically send them samples every time,” Parajon added.

Recent improvements have made the technology more lifelike. Browzwear recently did a demonstration for Beaverton, Ore.–based Nike Inc., showing Nike executives how close the athletic apparel giant could get to real life using Browzwear’s V-Stitcher. Browzwear designers showed their 3-D model side-byside with a Nike fit model. Nike is now a Browzwear customer.

Burg said Opti- Tex has made its 3-D software more accurate. The application has more than 40 points of measurement and a cloth-simulating engine that reproduces the effects of movement on a garment via a 3-D computer model. OptiTex allows for the integration of its 3-D tools into its CAD system without the need for file conversion—which saves time, said Burg. “We won’t replace fit models any time soon, but it’s very effective,” he said.

Speed is the key for Montreal-based CAD developer PAD System Technologies Inc., which recently upgraded its Haute Couture 3D module by integrating Kailua, Hawaii–based Syflex LLC’s cloth-simulator engine. The plug-in tool replicates how fabrics twist and turn during movement, giving the 3-D form a more lifelike appearance and giving designers a better picture of how clothing will actually look and move. The combination has also helped PAD venture further into the entertainment business, as motion picture studios and animators have been using the software to create garments for animated characters and create special effects for movies.

For the apparel industry, Syflex adds a new dimension to production, said Julie Lefebvre, 3-D manager for PAD.

“It can help you to see how a pattern reacts with chiffon versus a stiff denim,” Lefebvre said. “It interprets and simulates the process using a rather complicated algorithm, but the main idea is to simplify sample making.”

Other suppliers are also taking advantage of new 3-D technology. Los Angeles–based Shapely Shadow Inc. uses a 3-D laser to scan fit models to create repeatable dress forms that are accurate to one-eighth of an inch. Manufacturers and retailers can collaborate with their overseas operations because everyone is using the same dress form.

The company recently added a silicon composite model for lingerie makers. The pliable model replicates not only the shape of the human form but also the feel of the human body, which is important to makers of brassieres and other undergarments, noted Ilona Foyer, Shapely Shadow’s chief executive officer.

“It’s like flesh,” Foyer said of the silicon. “You can see where a bra or something may be too tight by how it affects the form. You can also see what type of cleavage it can produce,” she explained.

The company has expanded its business model to include collaborative software, which allows product developers to interact via computer terminals through a 3-D image.

Foyer recently signed on Fort Myers, Fla.–based Chico’s FAS Inc. and Anaheim, Calif.–based Pacific Sunwear of California Inc. as clients.

Foyer sees no boundaries for her dress forms. She even created one for animals.

“Don’t laugh. Saks Fifth Avenue has a $1,500 Gucci outfit for dogs, and we’re seeing clothes for dogs elsewhere, too,” she said.