Huntington Yarn Mills: Maker of Quality Yarns Manufactured in the USA

As Majid and Fay Jaraha man their Huntingdon Yarn Mill booth at summer’s Spinexpo in New York, they are getting used to the amazed looks they receive from some of the biggest fashion names in the United States, and not simply for the exceptional quality of their product. “We were swamped by designers from Ralph Lauren, Eileen Fisher, Elie Tahari, Coldwater Creek,” Fay recalls. “It was a shock to some of the designers that there actually is a textile mill still in operation in this country,” Majid continues. “For some reason, people don’t think we exist anymore.”

Exist they do. Huntingdon Yarn Mill has been continually operating its Philadelphia, Pennsylvania, plant since 1940, with only two owners—the founding Birkenbach family and the Jarahas. Majid, trained at England’s University of Manchester as a textile engineer, first came onboard as a purchasing agent 25 years ago, and then bought the mill a dozen years later. Fay was also educated in England as a fashion designer.

While over the years many American mills have fallen to overseas competition, under Majid’s skillful control and vision—and mill workers who go back several generations—Huntingdon Yarn Mill has thrived. Huntingdon has accelerated into state-of-the-art production on the latest machines while at the same time preserving the unique capabilities of its older machines by tweaking and modifying them to produce one-of-akind product that is impossible to duplicate.

Huntingdon Mill produces high-end novelty twisted yarns and metallic supporting yarns for apparel, home furnishings, and other, sometimes industrial, uses such as the twisting of Kevlar as well as a fiber used in fighter jet filtration systems. “Everything we do is highly specialized,” says Majid. “We are not trying to compete with commodity types of yarns.”

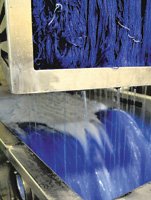

One of Huntingdon’s premier wool yarns, used in a signature wool crepe fabric, has been in the line for 60 years and had for years been the linchpin of one of the most prominent knit apparel companies in the United States. Huntingdon focuses on natural fi bers such as wool, cotton, rayon, kid mohair, linen, and silk, all of which are processed in unique ways. The yarns are then skein dyed in Huntingdon’s own dye house, one of the few skein-dye operations left in the country. Skein dyeing, in contrast to cheaper package dyeing, allows the yarn to “move and bloom,” Fay explains, by opening the yarn, fluffing and softening it for a superior hand.

Of the many yarns Huntingdon produces for apparel use, three stand out.

Velveteen yarn is an 80/20 combination made from the “best quality possible” wool fiber twisted with a high-quality rayon in gauges 7, 8, 10, and 14. The result creates a wool fabric that only needs a shake to come back to its original form. “This yarn is so good,” says Majid, “I remember a few years back, a customer called me and said, ’Can you make this yarn to last less time? Everybody loves it and once they buy it they don’t need to replace it.’”

There is also a 100 percent filament rayon for apparel and upholstery use that Fay explains is “the closest you can get to a silk yarn in look, feel, and how it acts.”

And then there are the “S” yarns, seed yarns worked on the re-mastered old machines to deliver a thick-and-thin, slubbed texture that is unique and adds “a touch of glory” when twisted with other yarns. The beauty of the modified old machinery, Majid explains, is that “our yarns are impossible to duplicate by machines overseas. This way, we are protecting ourselves and our customers because their material or fabric cannot be duplicated.”

Huntingdon is intent on working with customers small and large, and to that end they keep some 10 different yarns in inventory all the time, with a line of colors—up to 100 tones for some—for every yarn. They can also dye as little as 20 pounds, and sell one or two cones at a time, which not only makes it easier for a designer to experiment but also gives Huntingdon a leg up on overseas dyers who require larger orders and a great deal more turnaround time. The Jarahas also are active with the sewing industry, adding twists to any kind of yarn or plying any type of yarns together, and are fi nding domestic knitting mill sources for their clients.

“To have a mill and a dye house under the same roof, with the quality control and knowledge about the capability of the yarn, is the whole package,” Majid says.

It’s no wonder designers fl ocking to the Huntingdon Yarn Mill booth at Spinexpo were excited and delighted by their find. “Many of them are looking to bring a portion of their production back to the United States to be able to actively promote ’Made in America,’” Fay says, “and we are excited to be working with them toward this cause in the future.”

Huntingdon Yarn MillQuality, Creativity, Reliability(215) 425-5656www.hymill.com