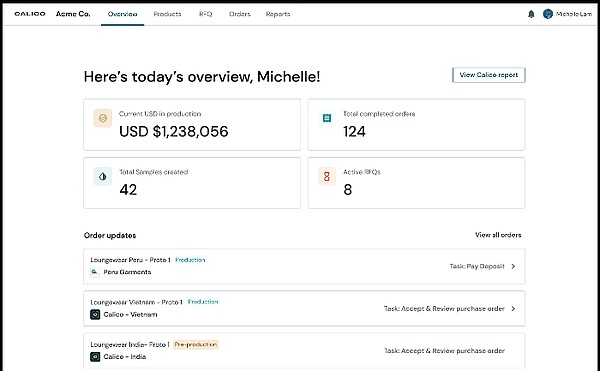

Calico provides an AI-powered smart supply-chain management platform that allows brands to run their supply chains without using spreadsheets and emails. Brands are able to reduce production errors and get products to market faster using Calico. Image: Calico

Calico Helps Brands Regain Control of Their Supply Chains

In an effort to tackle returns, the Toronto-based supply-chain OS company Calico aims to provide a smart solution that helps retailers streamline their supply chains, allowing them to solve the problem earlier rather than post-sale.

After starting D2C jewelry and apparel companies, Kathleen Chan founded Calico in October 2020 as a solution to the challenges she ran into while running her businesses. Calico provides an AI-powered smart supply-chain management platform that allows brands to run their supply chains from inception to development, moving away from the traditional spreadsheets and emails. The data-driven platform serves as a single point for brands and suppliers to streamline their supply chains by using real-time data and collaborative communication with their factories. With Calico, brands can reduce production errors, get products to market faster and access a network of vetted sustainable factories around the world.

“The beauty of Calico is that it centralizes all RFQs, POs and SKU information into one beautifully designed platform to provide end-to-end traceability of your supply chain,” said CEO Chan. “When all development processes are structured into custom milestones, both suppliers and brands can gain visibility into every stage of production—making products less error prone and more efficient. Starting at the component level, Calico’s platform enables clients to collaborate and connect during the design process to clearly define and develop their collections. From component libraries, SKU assortment, bill of materials, detailed tech packs and more, we bridge the gap between any product discrepancies that may translate into customer dissatisfaction.”

Following 300 percent growth in January 2022, in March Calico raised $2 million in seed funding led by the San Francisco–based Serena Ventures, an investment firm founded by tennis icon Serena Williams. Joining Serena Ventures in the funding round were Maple VC, Inovia Capital, Hyphen Capital and a group of early Shopify employees. Calico also received investments from leaders of big technology companies including Allen Shim, former CFO of Slack; Jeremy Lai, CEO of Italic; and Deborah Liu, CEO of Ancestry. The company previously received a pre-seed investment from Forum Ventures, bringing the company’s total raised to $2.15 million.

“We’re excited to partner with this world-class team on their mission to help brands take back control of their supply chain,” said Williams, who also owns the fashion brand S By Serena. “I have experienced the exact problem Calico is solving and have rarely come across a business as in tune with the industry’s challenges and limitations as Calico. It’s a category-defining product that will have an outsized impact on retail, and there couldn’t be a more critical time to help them [retailers] succeed.”

Retail returns rose to an average of 16.6 percent in 2021 up from 10.6 percent in 2020, with apparel brands seeing an average return rate of 12.2 percent due to wrong colors, size issues or material quality. Retailers must juggle between flexible return policies and minimizing the cost of returns in their supply chains while also dealing with higher customer demand and more industry competition. Customers have also adopted “bracketing” while shopping online—or ordering a product in different sizes or ordering more with the intent to return—ratcheting up return rates, and returns can run up to 30 percent of retailers’ supply-chain costs.

Through Calico, brands have been able to reduce production errors, accelerate time to market by 25 percent and partner with coveted manufacturers.

“When products are back in the hands of retailers, the chances of being sold again drop significantly,” said Chan. In fact, less than half of returned items are resold at full price—if ever. These returns are either passed through intermediaries and resellers who try to squeeze out any remaining profit, or they take an unfortunate path to landfills. This results in a massive environmental carbon footprint, serving as a clear indicator of our industry moving backwards,” said Chan.

Calico’s network of factories helps provide small manufacturers the capability to produce like larger brands. Chan said the platform chooses to work with factories that exceed their already strict environmental and ethical standards to ensure that all in the network have a strong commitment to sustainability and circularity.

“We look for a wide range of certifications across quality, ethical production and sustainability from SA8000 to WRAP. Choosing the right factory partners is important to us; not only must they be compatible with our brands but they must also approach manufacturing through an ethical and eco-friendly lens,” said Chan.